+86 131 9184 1111

+86 131 9184 1111

Sintered Mesh is generally constructed from multiple layers of stainless steel woven mesh after special laminate pressing and vacuum sintering. It is a new type filter material with higher mechanical strength and overall rigidity, and can be fabricated into filter elements in various shapes, such as round, cylindrical, conical, and pleated shapes. Sintered mesh has uniform pores and not easy to deform, thus delivering a stable filter rating and easy to clean property. In addition, we can offer sintered mesh made of Hastelloy, Monel and other alloys to meet the needs of different customers.

| Material: | stainless steel (304, 316L, etc.), Hastelloy, Monel, etc. |

| Maximum operating temperature: | 480 °C. |

| Filter rating: | 1–100 μm. |

Category:

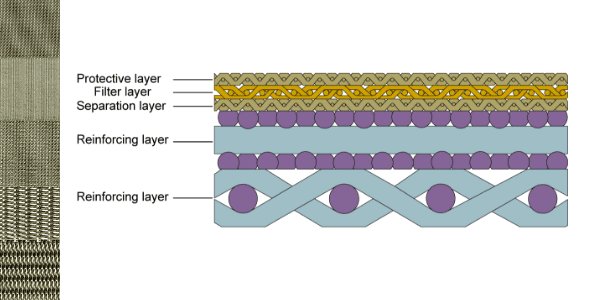

Standard 5-layer sintered mesh

A standard and the most widely used sintered mesh. It is a combination of 5 layers of wire mesh with different openings and mesh counts after laminating and vacuum sintering. We can also offer 6-layer sintered mesh that adds a 8-mesh or a 12-mesh square weave mesh on the 5-layer sintered mesh to offer higher mechanical strength and compression strength.

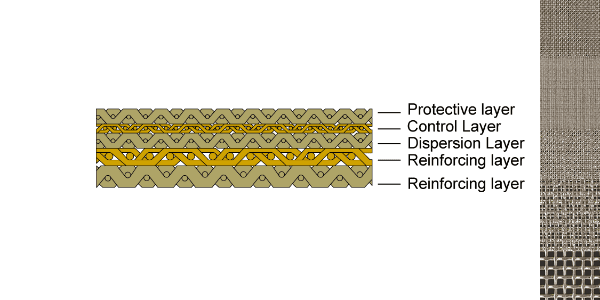

All square weave sintered mesh

It is made of multiple layers of square plain weave wire mesh after sintering. Square weave wire mesh has square hole opening and high open area rate, so this sintered mesh has excellent permeability, low resistance, high flow rate, etc. It is widely used in powder handling, drying and cooling and other fields with functional requirements, for example, acting as sintered mesh candle filter in chemical filtration applications.

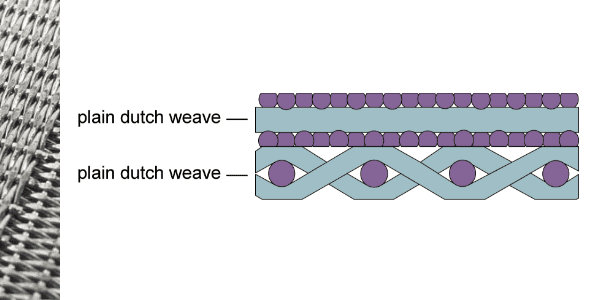

All Dutch weave sintered mesh

It is constructed of two or three layers of plain Dutch weave wire mesh after laminating and sintering. It has uniform opening distribution and stable permeability and is widely used in fluidized bed, powder handling, air drying, cooling, etc.

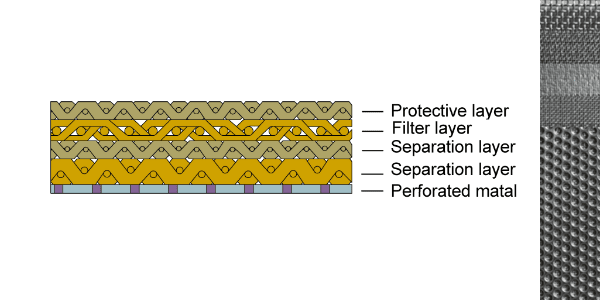

Perforated metal sintered mesh

It is fabricated by sintering multiple layers of square weave mesh (or Dutch weave mesh) and stainless steel perforated metal (round or square pattern) together. As a result, it combines the good permeability of woven mesh and the excellent mechanical strength of perforated mesh. In addition, it has great backwashing effect and low pressure lose and is widely used in mining, pharmaceuticals, grain screening, etc.

Features:

• High temperature sintering, high strength and durable • Stable filter rating

• Corrosion resistance and up to 480 °C high temperature resistance. • Stable opening size

• Equipped with 2 protection layers, not easy to deform • Can be cut, bent and welded.

Application:

Solid gas separation Muffler, silencer Air purification

Filtering oil Dedusting , Isolation dust , dust proof

Gas-oil dissociation Gas liquid separation

Moisture proof Heat insulation ,

Uniform gas,well-distributed, diffuse gas or oil or heat

Breathable protection Pharmaceutical , medicine

Chemical Chemical fiber

Filtration for high temperature environment

High pressure reverse wash filtering

Acid and alkali corrosion environment filtering

We can customized stainless steel wire mesh products

by your drawing and requirements

Our factory was established in 2008, it is now developed into a focus on production, development and sales of stainless steel wire mesh as one of modern science and technology enterprises

QUICK LINKS

Phone

+86 131 9184 1111

Location

Beizhang Zhuang Industrial Zone, Hengshui, Hebei, China