+86 131 9184 1111

+86 131 9184 1111

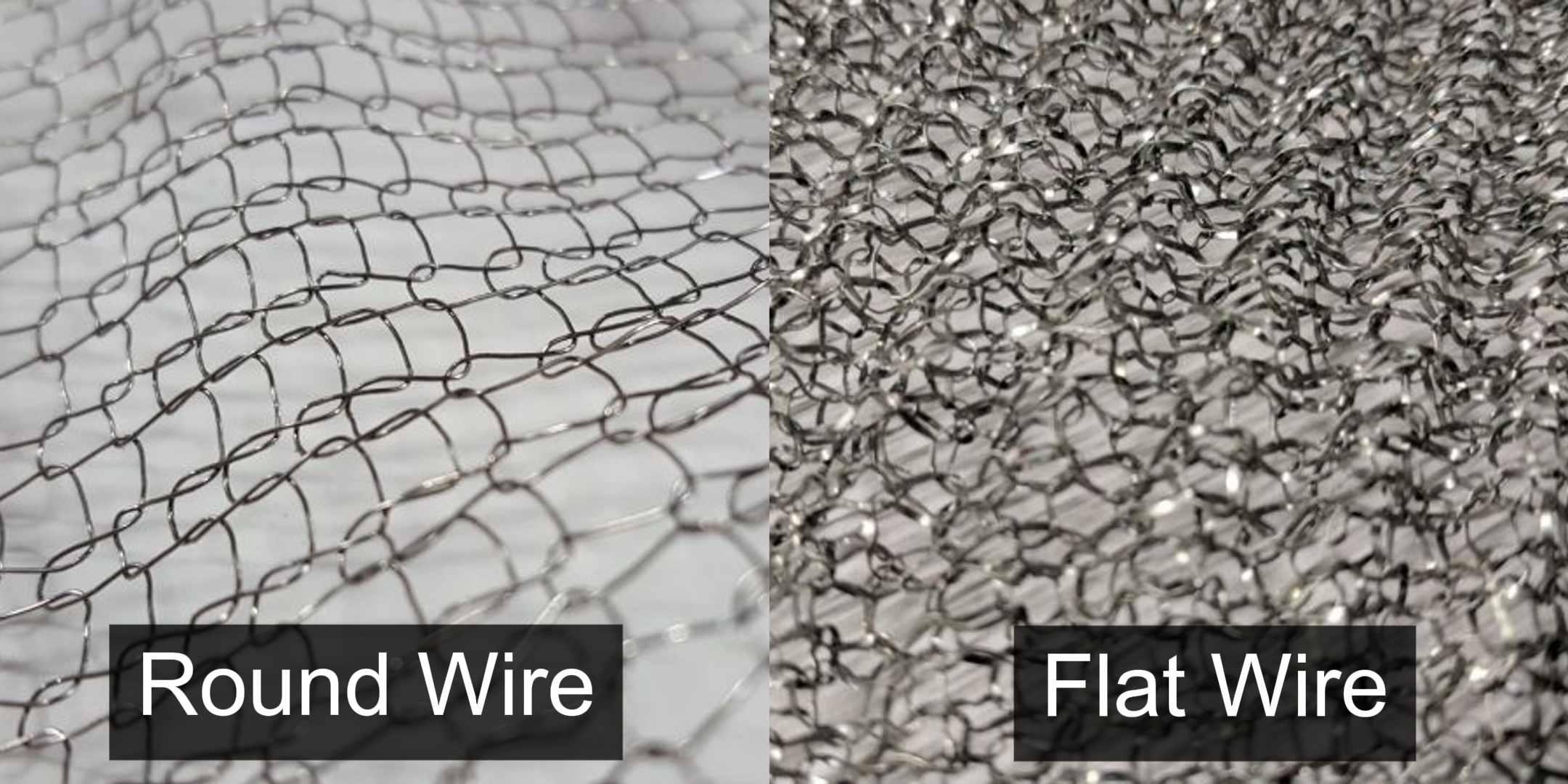

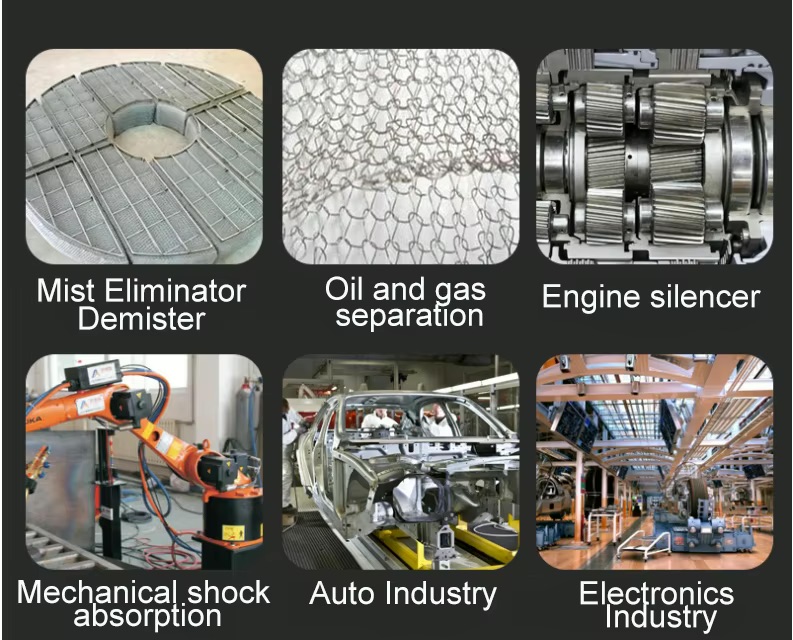

Knitted mesh is a continuous knitted mesh fabric produced by knitting metal wires on a circular knitting machine. This production process produces an extremely strong and flexible mesh fabric composed of a series of interlocking rings. It can be made of round or flat wires. The round wire knitted mesh is the most widely used type and the flat wire knitted mesh is used in special applications according to customers' requirements. It is widely used for gas-liquid filtration in the fields of petroleum, chemical industry, metallurgy, pharmaceuticals and for EMI shielding in the electronic field.

Description

| Material: | stainless steel wire, copper wire, brass wire, galvanized wire, nickel wire and other alloy wires; PP, PTEF and other non-metallic wires. |

| Wire type: | round wire, flat wire. |

| Strand type: | single-strand type, multi-strand type |

| Surface type: | flattened type, ginning type |

| Package: | packed with Kraft paper and then into the carton. |

Wire Type:

The round wire knitted mesh is the most widely used type and the flat wire knitted mesh offers a larger contact area and an enhanced separation efficiency.

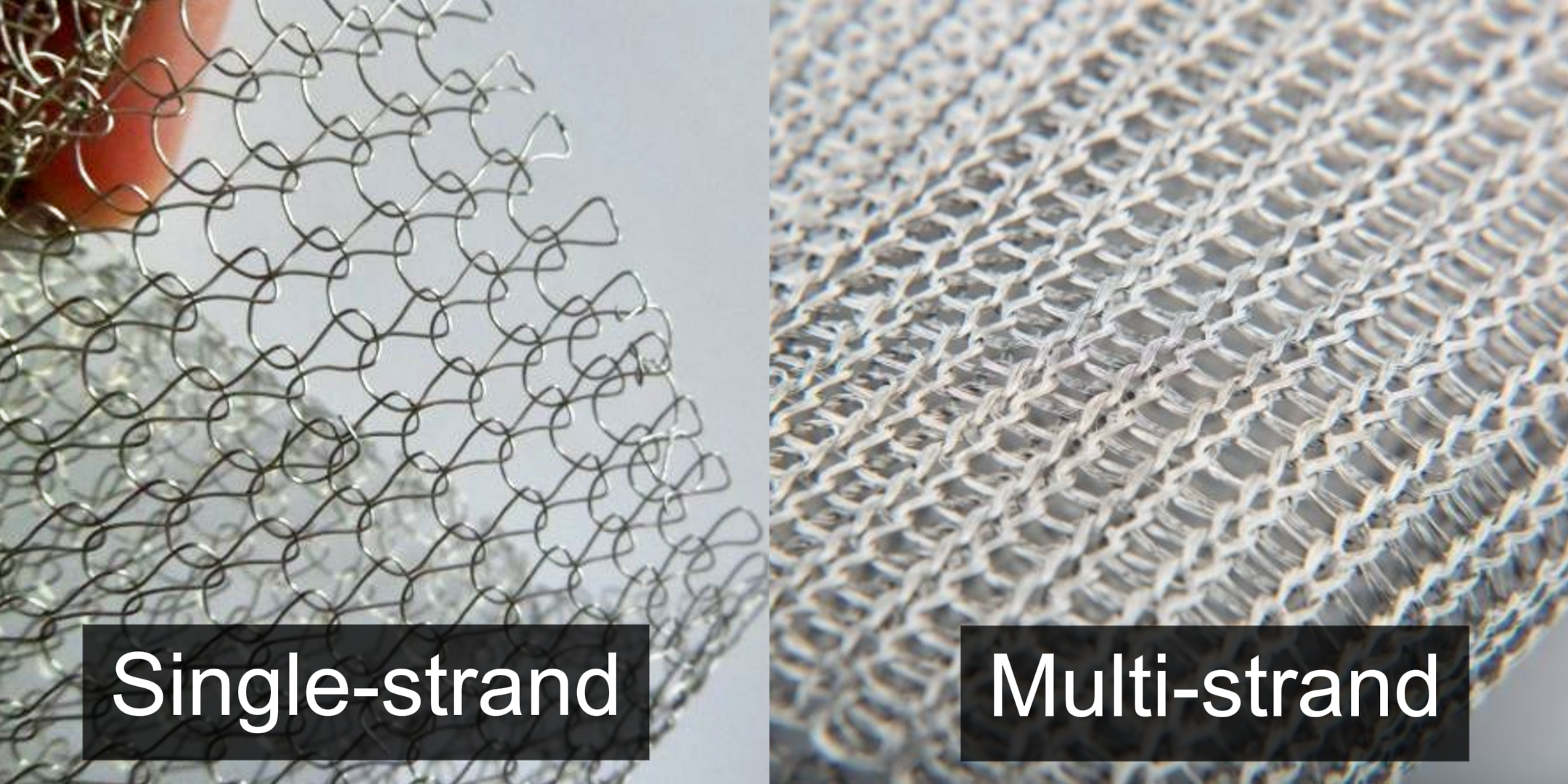

Strand Type:

Knitted mesh can be made of single-strand wires or multi-strand wires. The single-strand knitted mesh is simple and economical and is widely used in general-purpose applications. Multi-strand knitted mesh is made by knitting 3–12 strands metallic or non-metallic materials with a wire diameter ranging from 0.1 mm to 0.3 mm with knitters. In addition to the characteristics of common knitted mesh, it has a larger surface area and higher strength, and is mostly used in heavy duty applications, for example, the filtration and separation in chemical and petrochemical industries.

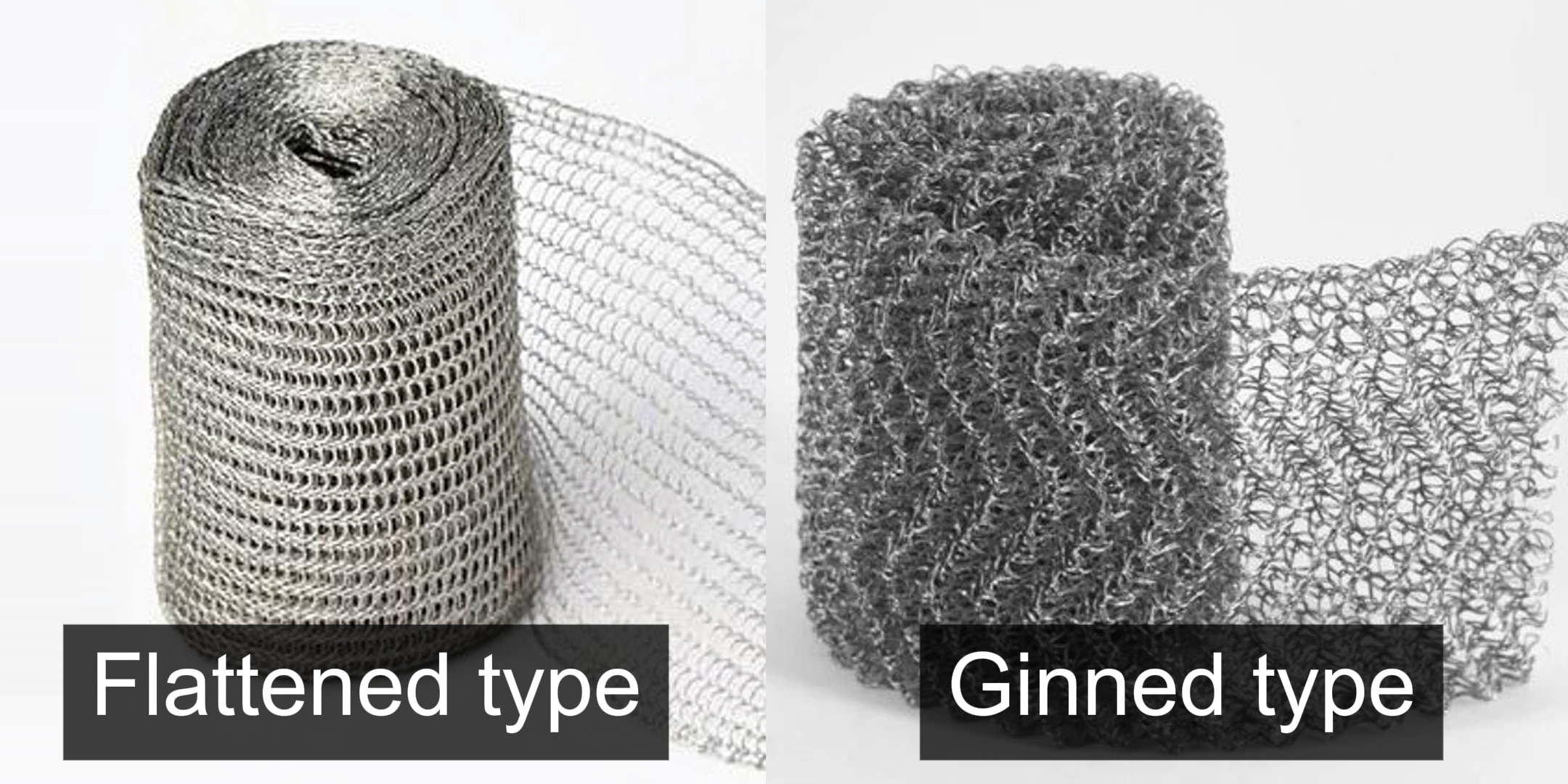

Surface Type:

Flattened surface is a standard surface type for general-purpose applications. When the knitted mesh is produced completely, it is ginned by special technology to form ginning in various shapes, widths and depths. It can be applied in a variety of industrial applications.

Knitted Wire Mesh Gasket:

Knitted wire mesh gasket are made of metal wire mesh or metal wire mesh over elastomer core for EMI and RFI shielding of electronic equipment.

Features:

• High strength and great overall stability • High filtration efficiency

• Excellent resistant to corrosion, acids, bases and high temperatures • Excellent cleaning capacity

• Durable and long service life • Soft and won't hurt the mechanical parts

Application:

It is widely used for gas-liquid filtration in the fields of petroleum, chemical industry, metallurgy, pharmaceuticals and for EMI shielding in the electronic field.

parameter

Technical data:

| Table1: Specification of Round Wire Knitted Mesh | ||||

| Type | Wire Diameter (mm) | Width(mm) | Number of Stitches Per cm on Length | Number of Stitches Per cm Across Lay Flat |

| Fine Mesh | 0.08–0.18 | 6–300 | 3.5 | 4.4 |

| Medium-Fine Mesh | 0.16 | 40–600 | 2.4 | 3.5 |

| Standard Mesh | 0.08–0.35 | 30–1000 | 1.6 | 1.9 |

| Coarse Mesh | 0.25–0.40 | 30–1000 | 1.6 | 0.74 |

| Super Coarse Mesh | 0.4–0.5 | 100–350 | 0.5 | 0.5 |

| Table 2: Specification of Flat Wire Knitted Mesh | ||||

| Wire Diameter (mm) | Mesh Opening/Loop Size (mm) | Number of Needles | Maximum Width (mm) | Minimum Width (mm) |

| 0.1 × 0.3 | 2 × 4 | 36 | 60 | 55 |

| 0.1 × 0.3 | 4.5 × 4,2.5 × 4 | 34 | 150 | 100 |

| 0.1 × 0.4 | 4.5 × 5.5,2.5 × 5.5 | 40 | 150 | 120 |

| 0.1 × 0.4 | 4 × 3.5,2.5 × 3.5 | 56 | 205 | 180 |

| 0.1 × 0.4 | 4 × 4,3 × 4 | 65 | 260 | 240 |

| 0.2 × 0.4 | 5.2 × 3.5,3 × 3.5 | 94 | 420 | 380 |

| 0.2 × 0.4 | 7.5 × 5,5 × 5 | 102 | 565 | 490 |

| 0.2 × 0.5 | 5 × 4,2.5 × 4 | 128 | 560 | 470 |

We can customized stainless steel wire mesh products

by your drawing and requirements

Our factory was established in 2008, it is now developed into a focus on production, development and sales of stainless steel wire mesh as one of modern science and technology enterprises

QUICK LINKS

Phone

+86 131 9184 1111

Location

Beizhang Zhuang Industrial Zone, Hengshui, Hebei, China