+86 131 9184 1111

+86 131 9184 1111

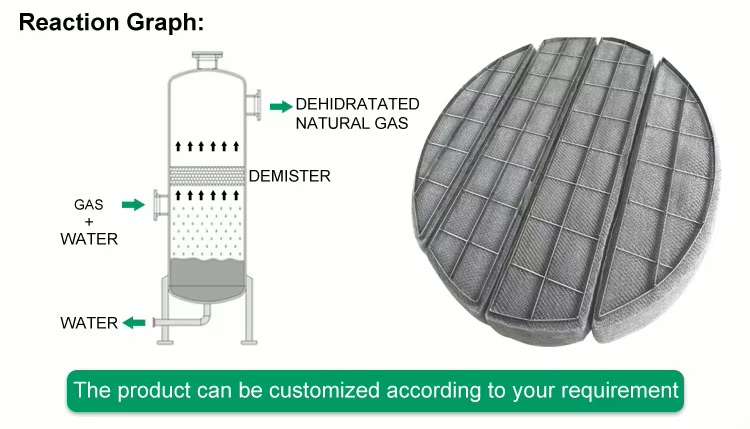

Demister pads, also known as demister, mister eliminator, vapor pad, is installed at the top of packed tower to used for removing micron-sized liquid particles from a vapor stream. It is widely used for the removal of liquid particles from exhaust air, exhaust gasses, and steam. Stainless steel, copper, Monel and other alloy as well as polypropylene and other non-metallic materials make demister pad be used in more corrosive and high temperature applications. Demister pads can help to improve the operating condition, optimize process indicators, increase the amount of processing and recovery of valuable materials, protect the environment, and decrease air pollution.

| Mesh Type | SP, DP, HP, HR |

| Mesh Pad Thickness | 100 mm, 150 mm,or other size can be customized |

| Grids Size | 25 mm*3 mm flat bar or 6 mm/8 mm round bar |

| Mesh Material | Stainless Steel,Alloy,Monel,Ti,Nickel,PP,PTFE,Fiber |

| Wire Diameter | 0.1 mm,0.15 mm,0.18 mm,0.23 mm,0.25 mm,0.27 mm,0.3 mm or multi-strand knitting |

| Common Mesh Density | 128 kg/M3; 144 kg/M3; 193 kg/M3; 220 kg/M3 |

Materials:

| Demister Pads Material | |

| Material | Products Separated |

| SS304 | For nitric acid, water steam |

| SS304L | For petroleum Fractions |

| SS316 | For fatty acids, reduced crude |

| SS316L | Reduced crude containing acid & other corrosive |

| Copper | Alcohol, Aldehyde, Amines |

| Monel | For caustic soda & other alkali, dilute acid |

| Nickel | For caustic soda, food product |

| Alloy 20 | Nitric acid, alkaline PH |

| Teflon FEP | For Highly corrosive conditions |

| Hostaflon PTFE | For Highly corrosive conditions |

| Inconel 825 | For dilute acid media & alkaline solution |

| Inconel 625 | For phosphoric and fatty acid |

| Polypropylene | For hydrilic acid, corrosive service at moderate temperature |

| P.V.D.F. | Corrosive Service for Temperature 140 °C |

| P.T.F.E. / FEP / PFA / ETFE / ECTFE | For highly corrosive and high temperature |

| Hostaflon | Sulphuric acid plant, temperature up to 150 °C |

| Glass Wool | For very fine mists |

Features:

• Large surface area and high separating and removal efficiency.

• less maintenance and service required.

• Adapt to any corrosive and temperature conditions.

• Control emissions discharge and reduce air pollution

• Eliminate or reduce equipment damage caused by corrosion

• Increase the amount of processing and recovery of valuable materials

Application:

Chemical Process Industry Power Generation

• Absorbers • Desalination Plants for Sea Water

• Distillation and Rectification Columns • Flue Gas Desulphurization (FGD)

• Gas Compression • Steam Drums

Oil and Gas Production Power Generation

• Amine Absorbers • Desalination Plants for Sea Water

• Separators • Flue Gas Desulphurization (FGD)

• Glycol dehydration • Steam Drums

Specification:

| Demister Technical Data | ||||

| Item | Density (kg/m3) | Free volume (%) | Surface area (m2/m3) | Application |

| HJP-80 | 80 | 99.0 | 158 | Moderate fouling, minimum press drop, dirty service |

| HJP-144 | 144 | 98.2 | 280 | Heavy duty, e.g. oil & gas separators |

| HJP-128 | 128 | 98.4 | 460 | Light fouling, high velocity, dirty service |

| HJP-193 | 193 | 97.5 | 375 | General purpose, optimum efficiency & pressure drop, heavy duty |

| HJP-220 | 220 | 97.2 | 905 | General purpose, optimum efficiency & pressure drop, high corrosive condition |

We can customized stainless steel wire mesh products

by your drawing and requirements

Our factory was established in 2008, it is now developed into a focus on production, development and sales of stainless steel wire mesh as one of modern science and technology enterprises

QUICK LINKS

Phone

+86 131 9184 1111

Location

Beizhang Zhuang Industrial Zone, Hengshui, Hebei, China